Egg packing plant

OVOVITA Egg Packing Plant exploits modern egg packing and sorting technologies. Thanks to complete automation of all lines, the delicate load constituted by the egg, does not come in contact with human hands at any time.

The total efficiency of two modern sorting and packing lines of the leading MPOBA manufactures amounts to quarter of a million eggs per one hour. The manufacturing technology encompasses the following listed phases:

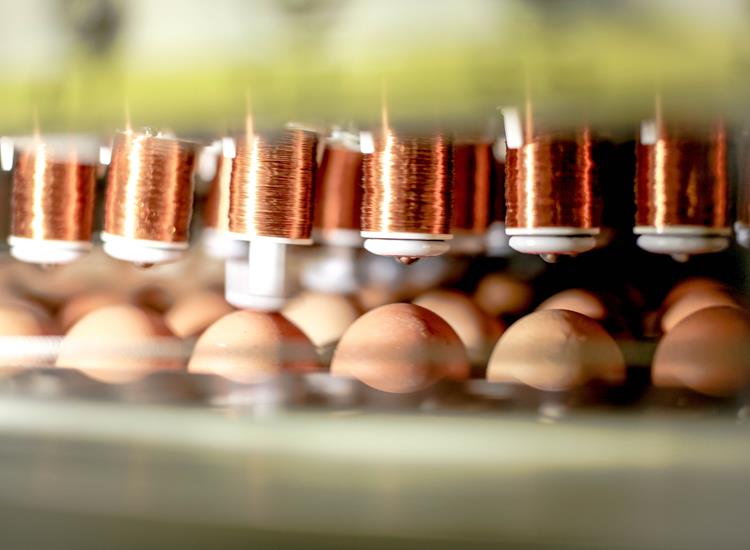

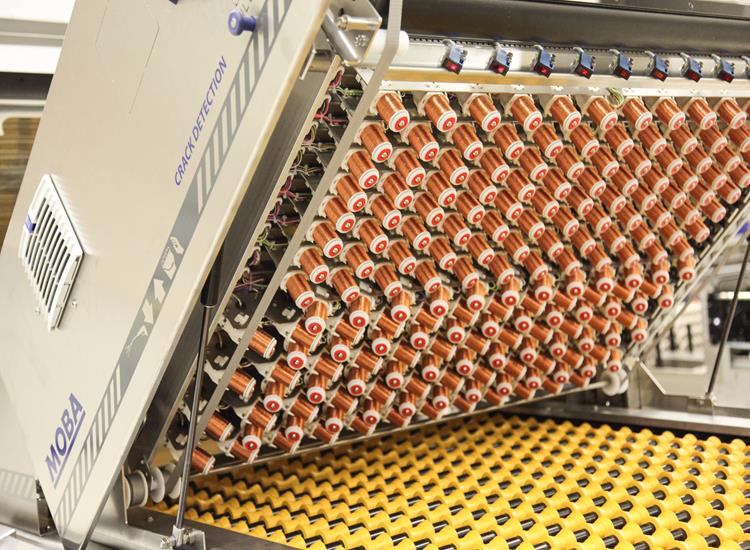

- detection of remnants of broken egg peels executed with the application of the Crack Detector technology – almost 400 sensors is able to detect the smallest potential micro-cracks of egg shell;

- detection of dirty eggs as well as broken eggs with the application of the vision detection system -Egg Inspector;

- UV disinfection;

- sorting eggs to particular weight classes;

- packing into retail, transport as well as bulk egg packaging followed with distribution and placement upon a palette.