Egg processing

OVOVITA egg processing plant manufactures liquid, dried as well as cooked egg products. 10 thousand of square metres indoors allow us to house kilometres of various technological lines. The manufacturing technology applied by the plant encompasses the following listed phases:

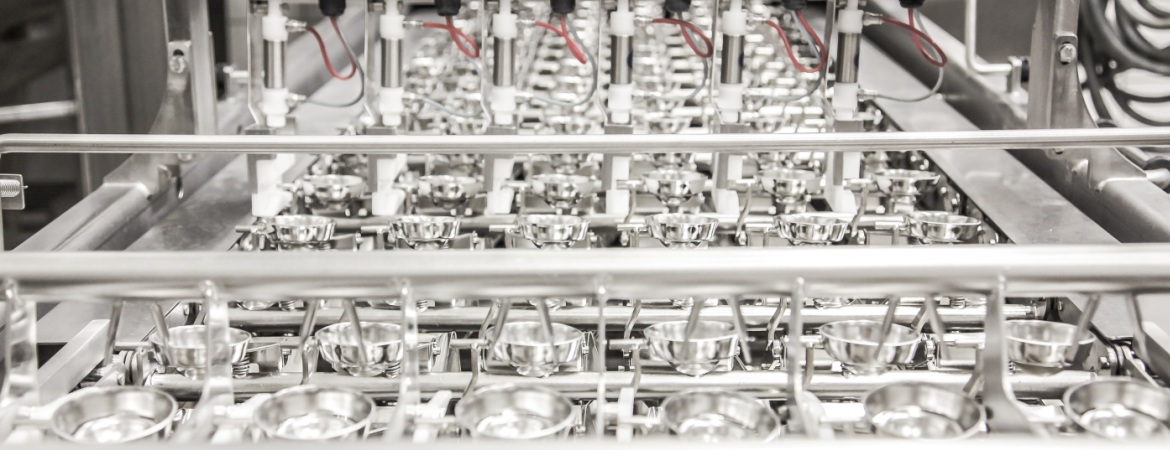

- cracking and separation of egg parts featuring electronic scanning of separation effectiveness;

- cooling and filtration;

- homogenisation;

- aseptic pasteurisation and liquid product packing;

- membrane ultra filtration;

- drying of egg yolk, white as well as of the whole egg;

- cooking, peeling and packing of hard cooked eggs in protective atmosphere.

The modern high storage warehouse capable of storing 50 million eggs ensure for the attainment of the indispensable level of resource in reserve. Computer steered climate and attainment of cooling conditions guarantees adequate storage conditions for all warehoused resources